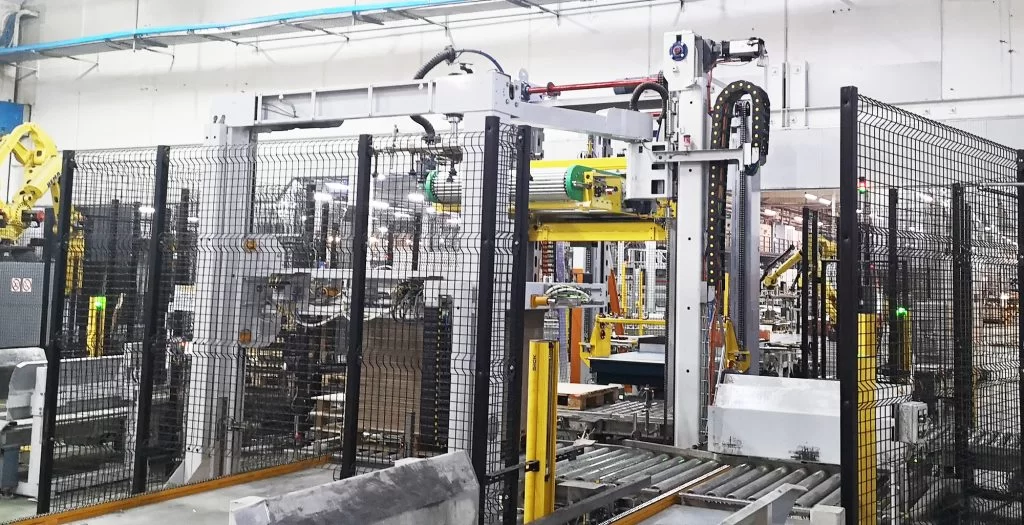

The frequent structural failures of the palletizing system column led a Lazio-based company, specializing in soft drink production, to overhaul the entire system. The process for palletizing non-alcoholic beverages, consisting of a single column, kept failing due to mechanical wear, resulting in machine downtime. The intervention involved completely replacing the mechanical part and implementing the system anew. The upgrade of the palletizing system involved installing a new portal-type forPAC system with a tracker. This is a highly efficient production machine that can be customized according to various requirements. It wasn't just about hardware. The plant upgrade intervention also involved the software side. In fact, the new palletizing system was equipped with an IO-Link system.

Communication Protocol for Data Management

and Component Update

Born from the experience of Balluff, a German company that is a global leader in the production of sensors and automation solutions, IO-Link is the ideal technological choice to achieve faster, more flexible, and efficient production. This serial communication protocol, based on open standards, allows for bidirectional data exchange between sensors and devices. This translates into greater flexibility of the plant. But that's not all. It is a technology that enhances machine performance and also improves the maintenance phase. In this regard, in the event of replacing any component in the field, reprogramming will not be necessary. This process optimization ensures that downtime during maintenance is shorter, as each component self-configures.